Press release I Mežica I 25 October 2023

European Union-Funded Mining Robot Achieves Remarkable Success in Slovenia Field Trials

A state-of-the-art mining robot, developed as part of the European Union-funded ROBOMINERS project, has achieved remarkable success during rigorous testing in Slovenia. These groundbreaking trials were conducted at the historic Mežica and Žerjav lead and zinc underground mines and signify a pivotal milestone in the project’s mission to enhance European access to mineral raw materials while reducing import dependency.

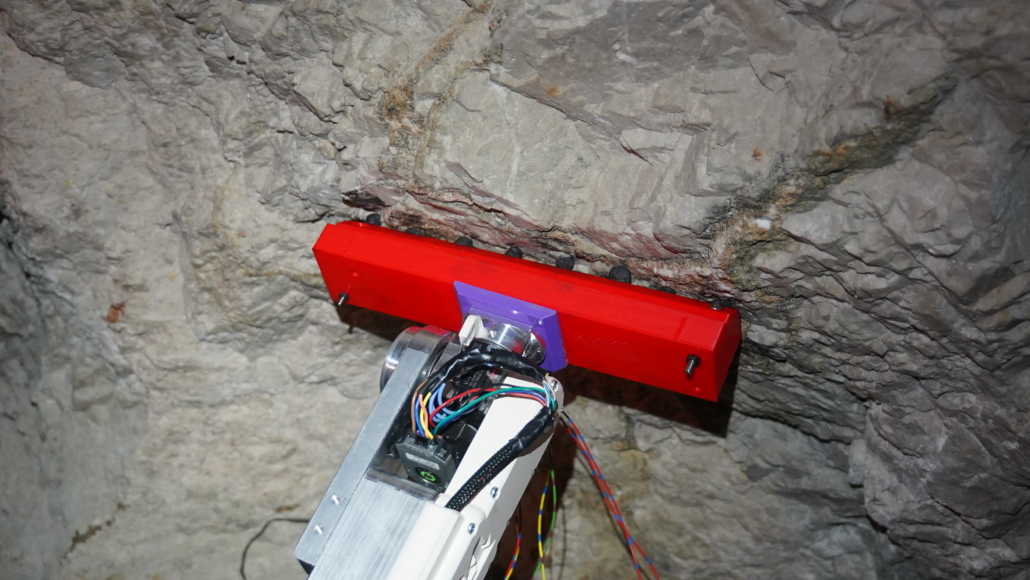

Sensor testing at Zerjav mines. Photo: ROBOMINERS.

The ROBOMINERS project, initiated in June 2019, has a resolute goal to revolutionise the extraction of raw materials, including strategically vital metals crucial for the ongoing energy transition, from domestic sources within the European Union. The consortium, comprising 14 partners from eleven European countries, has harnessed cutting-edge technology to create a bio-inspired robot tailored for challenging or relatively small deposits. Given the multiple risks associated with underground mining, the automation of this field is of paramount importance.

The ROBOMINERS prototype boasts a wide array of functions, including navigation, perception, excavation, material transport, and in-line material analysis. Rigorous experiments have yielded detailed insights into the technology’s suitability for varying rock conditions, resulting in significant enhancements in its excavation performance.

The field trials conducted in the Mežica and Žerjav abandoned lead and zinc underground mines, Slovenia, play a pivotal role in validating key sensing functions of the RM1 prototype, ultimately advancing Technology-Readiness-Level (TRL) of sensors to level 5. Among others, remote Laser Induced Breakdown Spectroscopy (LIBS), induced polarisation, electrical tomography systems and UV fluorescence sensors were tested and validated in real underground mine environment. Through this series of tests and demonstrations relevant to future mining operations, the ROBOMINERS project aims to provide tangible evidence of its successful completion and its potential to revolutionise the mining industry, where the RM1 prototype can be deployed for efficient and sustainable mineral extraction.

Project coordinator Claudio Rossi, from the Universidad Politécnica de Madrid, stated: “After four years of dedicated work, numerous pieces have seamlessly converged, culminating in successful real-world testing that validates our earlier laboratory findings and focused field tests. Throughout 2022, our efforts were predominantly concentrated in the lab, where we fine-tuned the production tool, honed navigation and geological modelling, and conducted field trials in a Belgian mine to assess geophysical sensors and the RM3 robotic platform’s touch-based sensors for 3D mapping and navigation. Furthermore, we rigorously tested real-time slurry analysis mineralogical sensors in a controlled experimental setup at K-UTEC, employing a slurry circulation system equipped with LIBS sensors. In the recent field trials, we had the opportunity to showcase a multitude of the RM1 mining robot’s functionalities and engage in vital dissemination activities.”

Underscoring ROBOMINERS’ commitment to enhancing Europe’s access to vital mineral resources while decreasing dependence on raw material imports, the project team will present the results of the Slovenia trials during its final conference within the scope of the European Union’s annual Raw Materials Week in Brussels on 14 November 2023.

Control room at Zerjav mines. Photo: ROBOMINERS.

Media contact:

Project coordinator, Universidad Politécnica de Madrid (UPM-Car):

Claudio Rossi – claudio.rossi@upm.es

Communication Manager, European Federation of Geologists (EFG):

Anita Stein – anita.stein@eurogeologists.eu

Local organiser – Geological Survey of Slovenia, Podzemlje Pece d.o.o. and Gradbeni materiali, d.o.o.:

Gorazd Žibret – gorazd.zibret@geo-zs.si